PR203/PR205 Series Temperature and Humidity Acquisitor

Product presentation

產品規格

產品介紹

Remote monitoring/operation, easier because of our APP

The PR203/PR205 series acquisitors, with accuracy of 0.01%, are the special portable devices for testing temperature and humidity uniformity. Up to 72 channels’ TCs, 24 channels’ RTDs, and 15 channels’ humidity transmitters can be connected. With the powerful human interface, they can display the electric data and temperature or humidity data of each channel at the same time. And the test and analysis of items such as temperature control error, temperature and humidity field, uniformity and stability of heat treatment furnaces and test equipment of temperature (humidity) environment can be automatically completed by this series of products when they are connected to a PC or cloud server through wired or wireless means. In addition, adopting a closed design, the products can work for a long time in dusty and harsh environment such as workshops.

一. Features

Under the premise of ensuring the accuracy of 0.01%, data acquisition can be performed at a speed of 0.1 S/channel. In the RTD acquisition mode, data acquisition can be performed at a speed of 0.5 S /channel.

The data of all temperature and humidity channels can be automatically corrected according to the existing customer configuration. In addition, the PR203 series acquisitors, with a correction data management function, can pre-store multiple sets of correction data to match different batches of test sensors.

The aluminum alloy thermostatic block with the built-in high-precision temperature sensor can provide CJ compensation with an accuracy better than 0.2℃ for the thermocouple measurement channel. Combined with 0.01% electrical measurement accuracy and the application of low-potential scanning switches of the PR203/205, they can easily meet the demanding requirements of the AMS2750E specification for test instruments.

In this mode, before the acquisition, whether all channels are connected to sensors can be automatically detected by the aquisitor. During the acquisition, the channels that are not connected to sensors will be automatically closed according to the acquisition results.

There are many usage restrictions when commonly used humidity transmitters are continuously operated in high humidity environments. PR203/205 series acquisitors can measure the humidity by using the dry-wet bulb method with a simple configuration, and measure the high humidity environment for a long time.

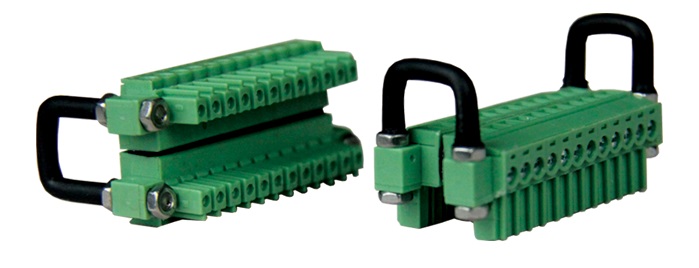

Channel expansion can be achieved by connecting supporting modules: under the TC module, additional 40 thermocouple test channels can be provided; under The RTD module, 8 resistance thermometer channels And 3 humidity channels can be added; under the WET module, 10 humidity channels can be added. In order to add the modules, the module and the aquisitor can be connected together only by the connection of a dedicated connector.

The PR203/205 series acquisitors can store acquisition data in a U disk during the independent operation. The stored data in the U disk can be browsed or processed with Excel, or imported into special software for data analysis and output as reports and certificates. In addition, PR2 solution: they have a built-in large-capacity FLASH memory, and support double backup of original data; the original data in FLASH can be viewed in real time and can be copied to a U disk by one clicking, which further enhances the data safety and reliability.

The PR203/205 series adopt the detachable large-capacity lithium battery for power supply and adopt a low-power design. Taking the PR205 series products as an example, in the case of battery-powered, they can work continuously for more than 20 hours, and can avoid measurement disturbances caused by the usage of AC power.

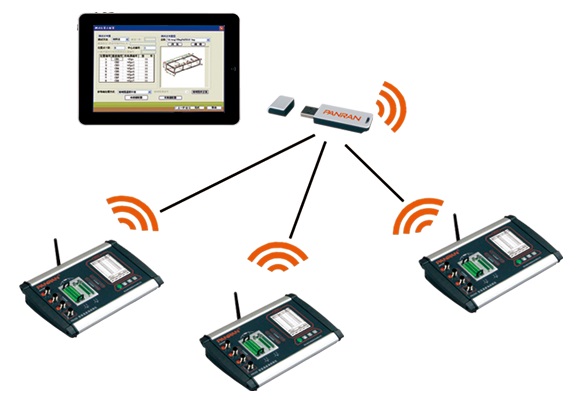

R203/205 series acquisitors can be connected to peripherals such as computers through 2.4G wireless local area networks. A wireless local area network can support multiple acquisitors to carry out temperature uniformity testing at the same time, which effectively improves work efficiency and simplifies the wiring process.

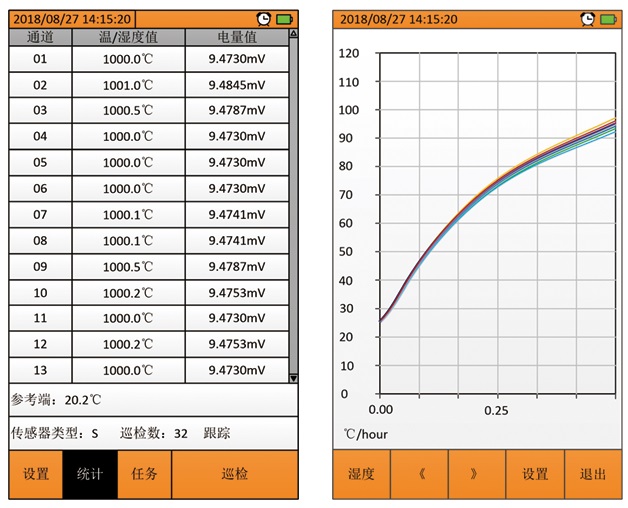

The human interaction composed of touch screen and mechanical keys can not only provide convenient operation, but also meet the reliability requirements in the actual operation. With a rich operation interface, what can be set include: channel settings, acquisition settings, system settings, curve drawing, data analysis, historical data viewing and data calibration.

The PR203AC temperature and humidity acquisitors are used in conjunction with the PANRAN smart metrology APP to realize many functions (such as the real-time remote monitoring, recording, data output, alarming) of the networked equipment; the historical data is stored in the cloud service, which is convenient for query and data processing; the software is with rich permission configuration module, so the user can independently manage the account of its unit; multiple users can be activated simultaneously online and different user authority levels can be configured.

|

Quick connector

Connection of platinum resistance

PR2056 RTD expansion module

Partial view of the back

Diagram of wireless communication

PR203 working interface |

Introduction to PANRAN Smart Metrology APP and Acquisition Module of Temperature and Humidity

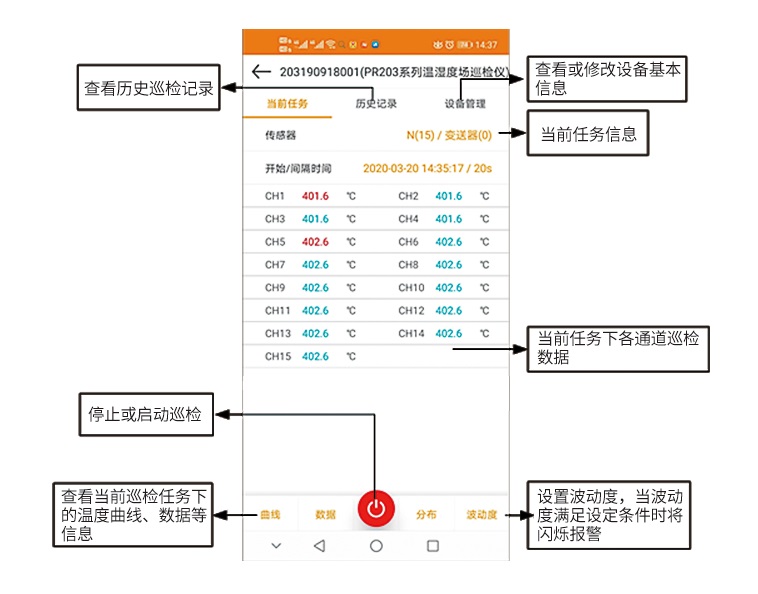

- Remote start and stop of acquisition tasks and real-time data monitoring

Remote start and stop acquisition tasks, real-time monitoring of acquisition data of temperature and humidity acquisitors, and marking of abnormal data can be operated by the APP on the mobile phone.

- Storage, calculation and management of cloud data

Establish a cloud data center and combined with special metrology equipment to provide customers with long-term data cloud storage and cloud computing.

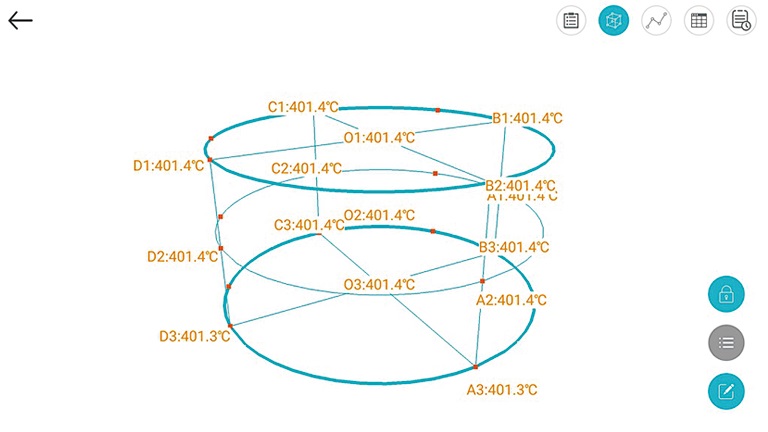

- Three-dimension display of real-time data

The three-dimension graphic template of the distribution points of the test location (the template can be created, loaded, edited, and deleted) can be customized, and the real-time temperature and humidity data of each location can be displayed stereoscopically by rotating the three-dimensional graphic.

- Data sharing function

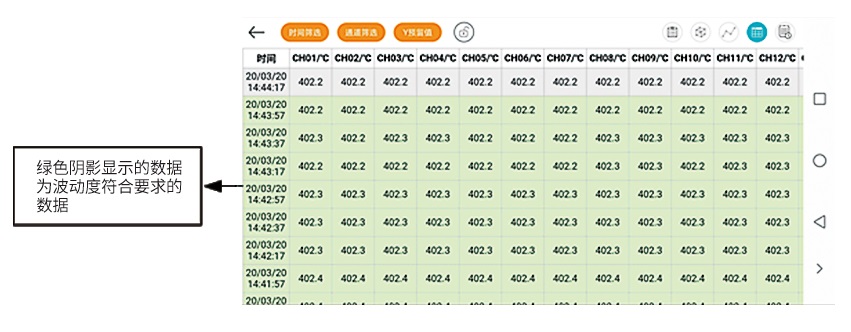

Through the APP, the acquisition data can be output as an EXCEL table file with one click, the data quality can be marked, and the cloud storage can be realized for convenient sharing and viewing on various terminals.

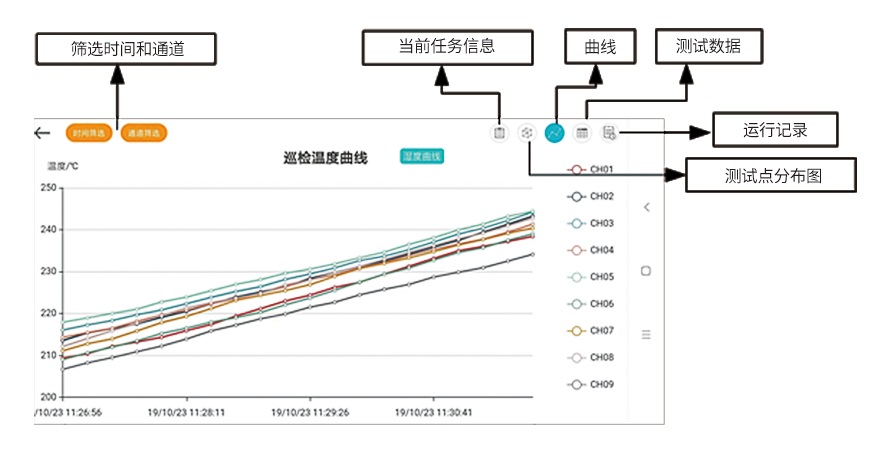

- The temperature and humidity curve of acquisition and data recording table can be drawn in real time

At the same time, the acquisition data is stored in the cloud service, so that the quality of the acquisition data can be monitored in real time without the metering personnel on site.

- Real-time monitoring of data quality

By setting the data of stability detection threshold, monitor whether the data meets the requirements in real time during the measurement process, send vibration reminders if the conditions are met, and mark the data that meets the stability requirements in the data list. This function can judge the validity and quality of the data in real time, which is convenient for improving the test efficiency.

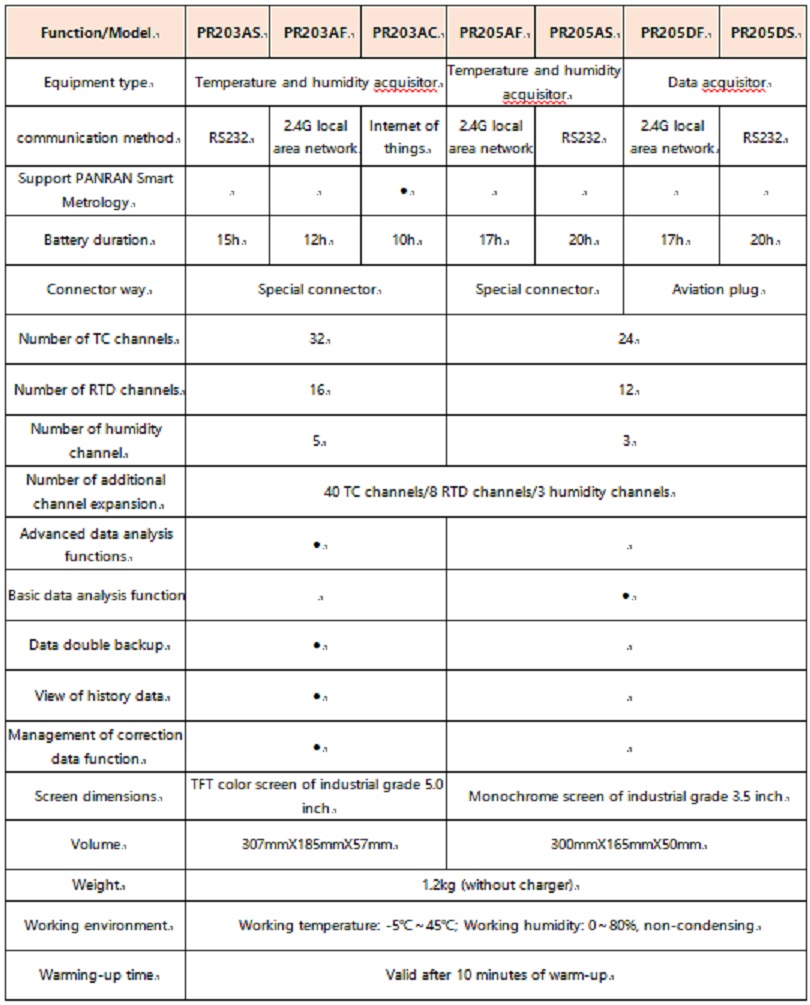

Specifications

|

Range |

Measurement scope |

Resolution |

Accuracy |

Number of channels |

Remarks |

|---|---|---|---|---|---|

|

70mV |

-5mV~70 mV |

0.1µV |

0.01%RD+5µV |

32 |

Input impedance≥50MΩ |

|

400Ω |

0Ω~400Ω |

1mΩ |

0.01%RD+0.005%FS |

16 |

Output 1mA excitation current |

|

Range |

Measurement scope |

Accuracy |

Resolution |

Sampling speed |

Remarks |

|---|---|---|---|---|---|

|

S |

100.0℃~1768.0℃ |

600℃,0.8℃ |

0.01℃ |

0.1 s/channel |

Conform to ITS-90 temperature standard |

|

R |

|||||

|

B |

250.0℃~1820.0℃ |

1300℃,0.8℃ |

|||

|

K |

-100.0℃~1300.0℃ |

≤600℃,0.6℃ |

|||

|

N |

-200.0℃~1300.0℃ |

||||

|

J |

-100.0℃~900.0℃ |

||||

|

E |

-90.0℃~700.0℃ |

||||

|

T |

-150.0℃~400.0℃ |

||||

|

PT100 |

-150.000℃~800.000℃ |

0℃,0.06℃ |

0.001℃ |

0.5 s/channel |

Output 1mA excitation current |

|

Humidity |

1.00%RH~99.00%RH |

0.1%RH |

0.01%RH |

1.0 s/channel |

Humidity transmitter error is not included. |

|

No. |

Codes |

Names |

|

1 |

GB/T 5170 |

Basic specifications calibration method of environment test equipment for electric and electronic products |

|

2 |

HB6783.3-93 |

Calibration method for climatic and environment test chamber for military airborne equipment |

|

3 |

GB/T5520-91 |

Electric drying box test |

|

4 |

JJF 1101-2019 |

Calibration specification for temperature and humidity of environment test equipment |

|

5 |

GB/T9452-2012 |

Testing method for working zone of heat treatment furnace |

|

6 |

QJ1428-88 |

Temperature control and measurement of heat treatment furnace |

|

7 |

GJB 509B-2008 |

Quality control requirement for heat treatment process |

|

8 |

HB 5425 |

Aviation parts testing method for working zone of heat treatment furnace |

|

9 |

AMS2750E |

Specifications for aeronautical materials |